| item | value |

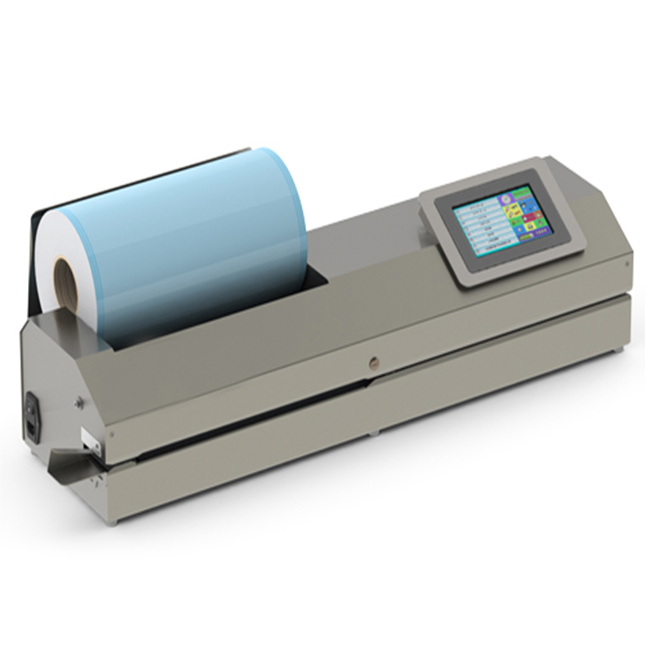

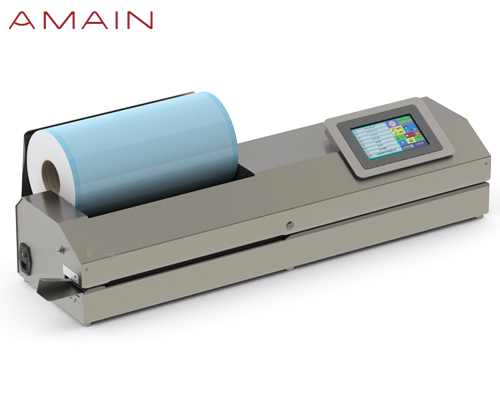

| Type | AMEF 120:Automatical feeding cutting and sealing machine |

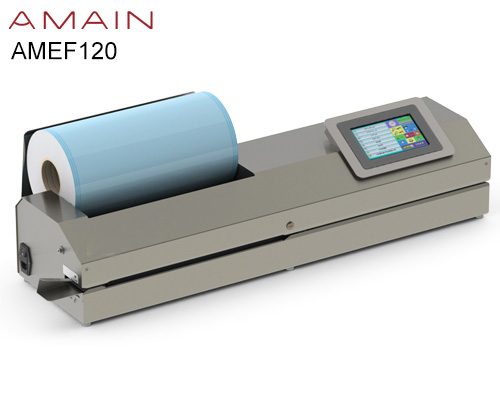

| AMEF 121:Automatical feeding cutting sealing and printing machine | |

| Applicable Industries | Sealing paper- plastic bags, 3D paper-plastic bags and paper-paper bags. |

| Function | AMEF 120:Automatical feeding cutting and sealing machine: Cutting and sealing of paper -plastic pouches can be realized separately or at the same time |

| AMEF121:Automatical feeding cutting sealing and printing machine: automatically feed, cut, seal the pouches and print out all the selected parameters in Chinese or English | |

| Sealing width (model is optional) | 12mm |

| Cutting Length | AMEF 120:at least 80mm |

| AMEF121:at least 50mm | |

| Application | Medical |

| Automatic Grade | automatic |

| Driven Type | Electric |

| Power supply | AMEF 120:110V/220V(+10%~-10%) 50Hz |

| AMEF 121:110V/220V(+10%~-10%) 50Hz/60HZ | |

| sealing speed | 10(+0.5~-0.5)m/min |

| seal left side | 0 ~ 35mm adjustable |

| Working Temperature | 60~220℃ adjustable |

| Ambient Temperature | 10~40℃ |

| Temperature error | Less than (+1%~-1%) |

| Maximum power | 500w |

| Place of Origin | China |

| Brand Name | Amain |

| Warranty | 1 Year |

| Seal strength | meets BS EN ISO 11607:2006 |

| AC Power | According to customer requirement |

| Key Selling Points | High precision control |

| Marketing Type | Hot Product 2020 |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Warranty of core components | 1 Year |

| After-sales Service Provided | Online Support |

| Keyword | medical sealing machine |

| Suitable for | Adjustable fixed-force system, suitable for sealing paper- plasticbags, 3D paper-plastic bags and paper-paper bags. |

| Usage | medical supplies |

| NO. | Model | Product Name | Specification | Max current(A) | Power(w) | Fuse | Weight(KG) | Dimension(MM) |

| 1 | AMEF 120-A | Automatic cutting-sealing machine | max cutting width≤400mm |

3.2 |

600 |

5A*2 |

38 | 962*290*200 |

| 2 | AMEF 120-B | max cutting width≤500mm | 650 | 40 | 1062*290*200 | |||

| 3 | AMEF 121-A | Cutting-sealing printing machine(Type of Printer: needle printer) | max cutting width≤400mm | 600 | 42 | 1030*290*200 | ||

| 4 | AMEF 121-B | max cutting width≤500mm | 650 | 45 | 1130*290 |

AMEF 120:Automatical feeding cutting and sealing machine: Cutting and sealing of paper -plastic pouches can be realized separately or at the same time

AMEF121:Automatical feeding cutting sealing and printing machine: automatically feed, cut, seal the pouches and print out all the selected parameters in Chinese or English.It is used in hospital disinfection supply center and other paper plastic packaging occasions,or can use as a sole cutting machine or sealing machine.

Product Features

AMEF 120 main Features:

1.Automatic feeding, cutting and sealing: You only need to set up the length and quantity of the paper-plastic pouches as per the requirements and start the program, then the machine will automatically complete the feeding, cutting and sealing process;

2.If necessary, several rolls of paper -plastic pouches with different widths could be loaded into the machine at the same time to improve its working efficiency by cutting off the edges simultaneously;

3.Multi- purpose machine: Cutting and sealing of paper -plastic pouches can be realized separately or at the same time;

4.”7″color LCD touch screen with Android operation system, which features in graphical operation interface, single chip

control system, in-built clock, and adjustable parameters setting and automatic storage with functions of voice reading, voice prompt and wireless Wife connection etc.;

5.In built LCD touch screen can be used to set up or change the operation parameters of the machine with a variety of Chinese input methods or optional scanning gun;

6.Temperature controlled by a microcomputer, accuracy +1%~-1%, random set up of working temperature range 60-220℃;

7.High-speed increase of temperature: only 40 seconds required from ambient temperature to 180℃; high efficient and energy saving;

8.Auxiliary temperature reduction design: The in built microcomputer controlled temperature reducing device reduces the waiting time from high sealing temperature to lower sealing temperature;

9.Safe operation: If the sealing temperature outranges the sting range for more than +4℃~-4℃, the machine will automatically stop working, which effectively guarantees the seal quality and safety;

10.Automatic failure alarm and automatic detection during working;

11.Complete optional accessories such as the multifunctional roller worktables and special silent roller transmission platform,scanning gun etc..

AMEF 121 main Features:

1.adopts 7″ large sized capacitive touch screen, graphic presentation, auto control interface, fully auto micro computer

temperature control with easy operation system and reliable working status. It integrated auto feeding, auto cutting and continuous sealing with Chinese -English printing, may set up of paper- plastic cutting length, sealing temperature, expiry date, sterilizer No. And sterilizing times etc.. It is a machine that of nice looking, compact in size, convenient to handle with high working efficiency and labor and time saving.

2.Automatic feeding, cutting sealing and printing: You only need to set up the length and quantity of the paper-plastic pouches as per the requirements and start the program then the machine will automatically feed, cut, seal the pouches and print out all the selected parameters in Chinese or English;

3.Multi -purpose machine: Cutting, sealing and printing to paper-plastic pouches can be realized separately or at the same time to Improve the working efficiency.

4. adjustable sealing margin: Depending on whether printing is necessary to improve the utilization rate of the pouch rolls by adjusting the distance between the cutting and the sealing edges;

5.if necessary, several rolls of paper-plastic pouches with different widths could be loaded into the machine at the same time to improve it a working efficiency by cutting off the edges simultaneously

6.In-built color touch control screen can be used to set up Or change the operation parameters with a variety of Chinese input methods of using optional scanning sun,and the printer Kill print out all the selected parameters;

7.Temperature controlled by a microcomputer, accuracy + 1%~-1%,random set up of working temperature range 60 ~220℃

8.High-speed increase of temperature: only 40 seconds required from ambient temperature to 180℃, high efficient and energy saving:

9.Auxiliary temperature reduction design; The in-built microcomputer controlled temperature reducing device reduces the waiting time from high sealing temperature to lower sealing temperature.

10.Safe operation: If the sealing temperature outranges the setting range for more than +4℃~-4℃ Safe operation the machine will automatically stop working, which effectively guarantees the seal quality and safety